Aligned Long Discontinuous Composite Additive Manufacturing

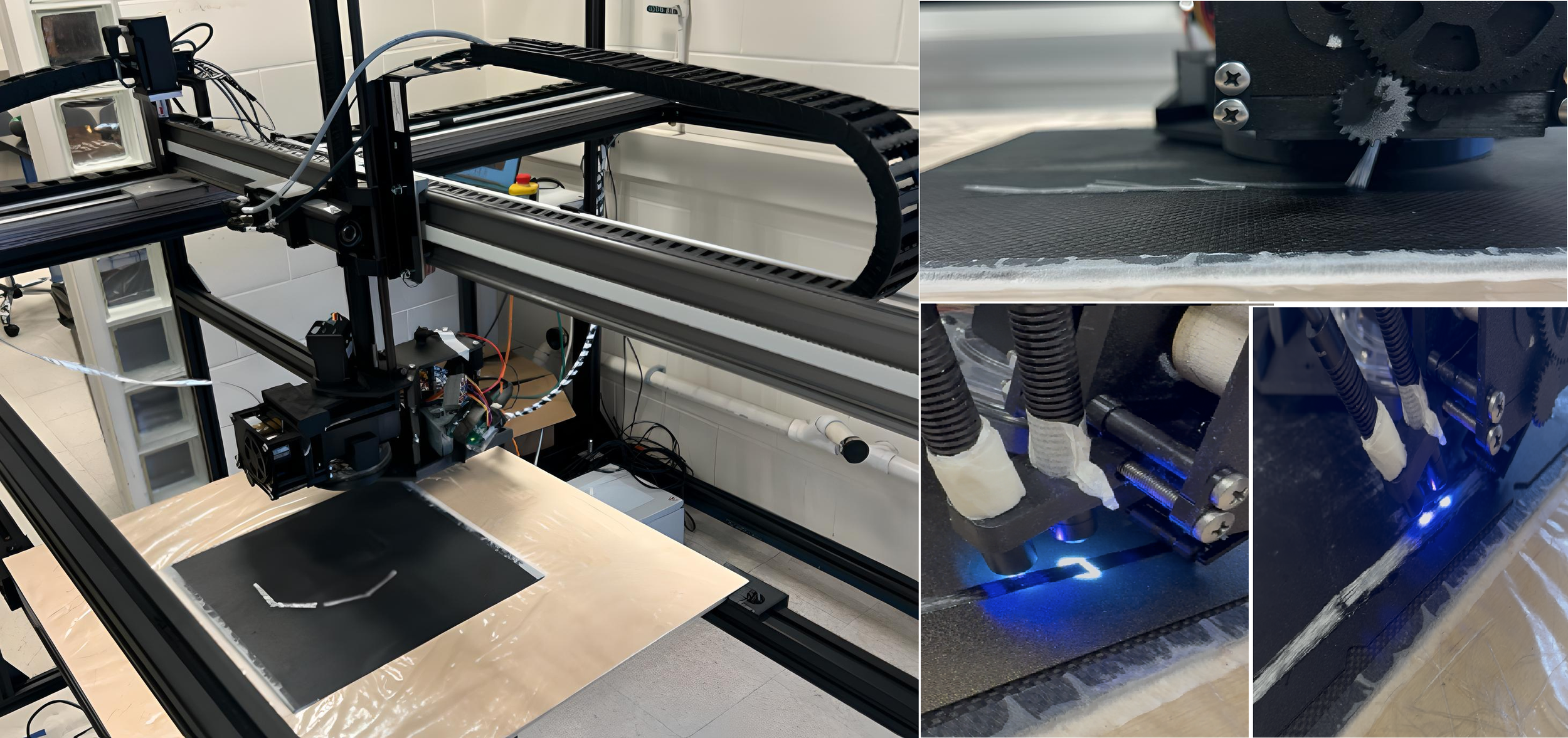

We are currently advancing an aligned long discontinuous composite additive manufacturing platform that enables thermoset 3D printing of large-scale parts up to 1.5 m × 1.5 m using a wide range of fiber types as raw feedstock. The objective is to optimize composite structures through programmable control of fiber alignment, fiber volume fraction, and fiber length, tailored to anticipated loading requirements and local performance demands. This approach supports the fabrication of lightweight thin-walled geometries as well as bulk plate architectures with spatially variable stiffness, allowing material to be placed and oriented only where it is structurally needed. The system is designed to deliver high-performance, scalable composite manufacturing with improved design freedom and production efficiency without sacrificing structural integrity.

Traditional methods for metal-composite joining typically employ adhesives or mechanical fasteners to bond dissimilar materials. Our approach innovates by utilizing laser texturing on the metal surface, followed by joining through simple heat compression. We are currently using a vitrimer resin, which combines the mechanical properties of a thermoset polymer with the reshaping capabilities of thermoplastics. Our research focuses on strategically shaping grooves during laser texturing to achieve effective interlocking with the polymer matrix. Additionally, we are exploring the incorporation of nanoparticles and milled fibers to enhance bonding strength.

Metal-Composite Joining

Recycle & Repair of Composites

Despite the favorable high stiffness-to-weight ratio of composite materials, significant environmental concerns remain, particularly regarding recycling and repair. Our current research focuses on both chemical and mechanical recycling processes for fiber-reinforced vitrimer composites. Through chemical recycling, we have successfully depolymerized composite parts, allowing for the recovery and reuse of fibers in multiple fabrication cycles. Additionally, we are investigating effective methods for repairing composites without compromising their mechanical properties.

Hybrid Surface Post-processing

Additive manufacturing (AM) has advanced significantly, allowing for the production of high-quality metal alloy components. This capability is increasingly prominent in structural aerospace applications due to its improved material characteristics. Unlike early metal AM methods, modern AM processes produce fully dense components with minimal porosity, often matching the properties of traditionally forged parts. However, achieving a satisfactory surface finish remains challenging.

To address the challenges of intricate AM structures, especially inner channels, our research group employs a hybrid post-processing approach that combines cavitation peening and electrochemical polishing (ECP). While ECP is effective in enhancing metal surface quality, it has limitations such as low material removal rate and limited impact on mechanical properties. By integrating ultrasonic cavitation peening with ECP, we have demonstrated that the synergistic effects of these processes not only increase material removal rates but also improve surface mechanical properties.